Peachey Conservation, LLC is based in New York City, and provides a comprehensive range of book conservation treatments and services to individuals, collectors, dealers, and institutions. All treatments are designed to preserve the historic, artifactual, and aesthetic aspects of books. Jeff Peachey, owner, has over 30 years experience working on all types of books, from incunabula to Grandma’s cookbook to 20th century Artist Books. Jeff is a Professional Associate in the American Institute of Conservation (AIC), and all treatments are preformed in accordance with the AIC Code of Ethics.

HOW DO I GET MY BOOK CONSERVED?

Please contact Jeff to inquire about commencing a treatment. He works with local, national, and international clients.

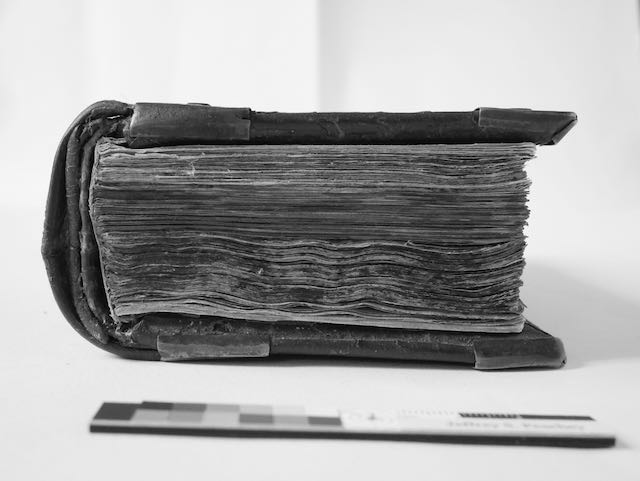

FEATURED TREATMENT: THE ONLY KNOWN COPY OF A 1564 AUSBUND

The 1564 Ausbund has a crazy backstory. According to oral lore, the book was torn in half in 1928 by the bookseller, since the buyer, H.S. Bender, could not afford the entire book. Bender purchased the back part, which contained the Ausbund, on behalf of the Mennonite Historical Library (MHL), for $10.00! In 1943 the front part was purchased by the MHL, but it took a number of years to realize both parts belonged together. The MHL contacted Jeff in 2015 for a condition assessment and treatment. The extensive treatment involved surface cleaning, page repairs, re-repairing old repairs, making a high resolution scan of the entire text, adding a textblock infill, resewing and reuniting the two halves, rebacking, and creating a custom enclosure housing the book with the original sewing remains.

An article about the Ausbund history and treatment, written by Ervin Beck and Peachey, is available to download below courtesy of Pennsylvania Mennonite Heritage (Vol. 39, No. 3, Oct. 2016) Used with permission, © 2016 Lancaster Mennonite Historical Society.

EXPERIENCE

For more than 30 years, Peachey has specialized in the conservation of books for institutions and individuals. Board reattachment is one of the most common treatments he performs, like on this Cobden-Sanderson binding and Gutenberg Bible. Protective enclosures are very important for long term preservation, and he created a new type of drop spine cradle box to store and consult fragile books, made the plans available open source, and it is now used internationally. Although he works on all types of books, one area of specialization is wooden board structures, and he co-wrote an article in The Journal of the Institute of Conservation about a new treatment method for them. Another area of specialization is early 19th century book cloth, and he currently manufactures a mid 19th century style textured bookcloth. He invented the Peachey Board Slotting Machine, used by dozens of institutions worldwide. Hand tools are very important to bench conservators, and he designs and makes improved and specialized knives and other tools that other conservators and bookbinders covet and use. Book history research informs his treatments, and has been supported many fellowships, including a Rockefeller Foundation Residency at the Bellagio Center in Lake Como, Italy, and the Patricia Fleming Visiting Fellowship in Bibliography and Book History from the University of Toronto, Canada. He is a Visiting Instructor teaching historic book structures for the Masters level Book Conservation students at Buffalo State University, New York University, and the Winterthur/ University of Delaware. More about his background in an interview from the Guild of Book Workers Newsletter. Full cv here.

PHILOSOPHY OF BOOK CONSERVATION

“Generally speaking, it is desirable that the characteristics of an old book should be preserved…. It is far more pleasant to see an old book in a patched contemporary binding, than smug and tidy in the most immaculate modern cover.” Douglas Cockerell, Bookbinding and the Care of Books, 1901 (p. 306).

I entered this field because I became fascinated by the sophisticated technology of the codex structure, and I strive to preserve all evidence of how a book was made, where it was made, and so on – evidence that can be obscured or removed by rebinding. There is still much to learn about the materials and techniques of historic bindings – which add context to the content – so we should preserve their essential nature by concentrating on minimally invasive treatments. A treatment should should stabilize the book, allowing it functionality without causing further damage. It should alter the aesthetic qualities as little as possible. The intrinsic aspects of books and paper artifacts — their physical construction, material content, aesthetics, and tactile qualities — are unique and irreplaceable. These are the aspects I preserve for future generations. Contact me to begin a treatment!