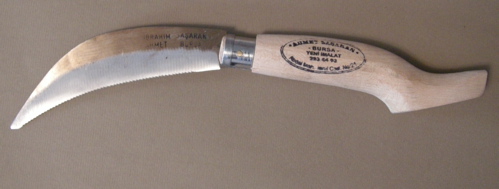

This is a small serrated folding knife. I wasn’t able to figure out what it was used for–the serrations are very fine. As you can see in the photo, the sides are ground slightly and taper towards the cutting edge. The back of the blade is about .020″, and it tapers towards the cutting edge which is a very thin .010-.007″. The shape is similar to a modern pruning saw which also has a pistol type handle. It was made in Bursa, Turkey, which is the center for metal working– like Sheffield in England, or Solingen in Germany.

I find the handle the most interesting feature since it fits comfortably into the heel of the hand. It cuts, Eastern style saw, on the pull stroke. It cost $4.00 and was quickly made- note the crude ferrule and pivot pin, however the complex curves on the handle must have taken some time. But it feels surprisingly solid.

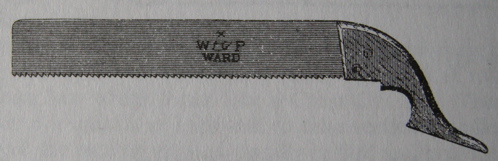

This illustration is from a Ward and Payne Ltd., Sheffield catalog, circa 1910’s. This is called a Turkish Saw (aka. Monkey saw) According to Salaman’s Dictionary of woodworking tools, they are common in Greece, Crete and Turkey and are used as a dovetail or small tenon saw. Again, it cuts eastern style on the pull stroke, so the blade can be made thinner. And like the knife above, the handle looks very comfortable, since it extends near to the wrist at the very end.