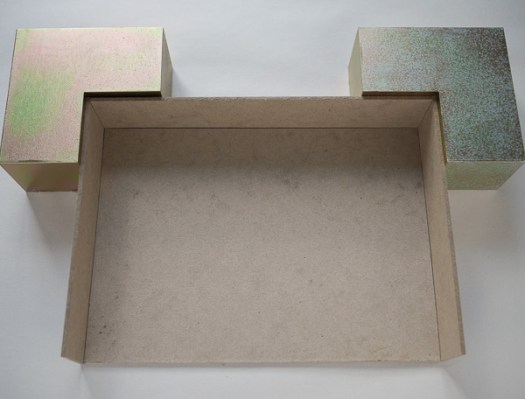

Jeff Altepeter, the other bookbinder named Jeff that is obsessed professionally interested in bookbinding tools, is the Bookbinding Department Head at North Bennet Street School. Recently he has begun manufacturing box making weights, often referred to as “L” weights, though it seems angle weights would be more descriptive. Whatever you call them, they are really, really nice. Not only do they speed production and increase accurate corner wall miters — so there is less sanding — but because of their clamping pressure you end up with a stronger join.

Jeff explains that “Tini Miura turned us onto the design [calling them “L” weights] years ago at the American Academy of Bookbinding and they used to be sold by Lucinda Carr of Jumping Bird/ Mesa Canyon Studios. When she lost interest in manufacturing them, I picked it up because my students here at NBSS fight over the sets I have in the classroom. They are useful when building the walls of boxes, measuring for boxes, and as nice single hand weights at about 7 pounds each.”

These are solid steel, precision machined on the inner faces and zinc plated. They are 2 inches square on the short ends, 4 inches on the long ones. Current cost is $160.00 for a set of two plus $25 shipping in the US. Up to two sets can ship at this price. Larger orders ship at cost.

Contact Jeff Altepeter to purchase: jaltepet <AT> gmail <DOT> com